Vacuum Chambers and Custom Fabrication

Tailored Solutions for High and Ultra-High Vacuum Applications

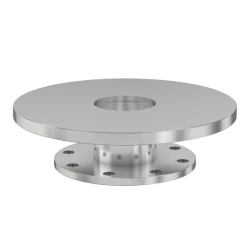

Pfeiffer, part of the Busch Group, offers a comprehensive line of vacuum chambers and UHV manifolds under the Nor-Cal Products brand for the US market. Manufactured in Yreka, California, these solutions reflect decades of vacuum expertise and precision fabrication.The Nor-Cal product line includes standard chamber configurations, modular components such as bell jars and base plates, and fully customizable chamber and manifold designs tailored to specific application requirements. Whether for research-grade use in universities and national laboratories or high-volume OEM production, Nor-Cal Products delivers reliable, high-performance vacuum solutions.

As a key part of the Busch Group’s vacuum technology portfolio, these solutions are frequently integrated with Pfeiffer and Busch products such as pumps, valves, and more, enabling seamless, system-level performance across a wide range of markets and applications.

Each Nor-Cal chamber and manifold is proudly manufactured in the USA, combining time-tested reliability with precision engineering.

Advanced fabrication technology and rigorous quality control processes ensure the production of high- and ultra-high vacuum chambers with verified leak test integrity, dimensional accuracy, and long-term reliability.

Vacuum Chambers and Custom Fabrication Features

- Stainless steel options: 304, 304L, 316, 316L

- Aluminum chambers available on request

- Stand-alone or complete assemblies with flanges, manipulators, viewports, and more

- Surface finishes: bead-blasted, electropolished, or chemically cleaned

- Helium leak tested to ≤ 1×10⁻⁹ mbar·L/sec

- CMM-inspected for dimensional accuracy; reports available

- Optional fiberglass wrapping for uniform bakeout and thermal distribution

Legacy Vacuum Chambers and Components, Built for Modern Demands

Request a quote for custom vacuum chambers, UHV manifolds, or precision vacuum components by completing our online form. Our team will follow up with a solution engineered to your specifications.

Common Questions about Vacuum Chambers

What are the advantages of a PV V&E chamber?

We know vacuum. All of our chambers are fabricated in-house by world-class vacuum welders. Because our chambers are manufactured in-house, Pfeiffer Vacuum Valves & Engineering have control at every step of the fabrication: design, manufacturing, electropolishing, RGA scans, bakeouts, vacuum testing, and shipping.

How can I reduce the cost of a custom chamber?

Peiffer Vacuum Valves & Engineering's team of engineers will work with you to reduce the cost of a custom-made chamber. Two easy methods to substantially reduce costs are:

- Reduce the tolerances on the drawing. Tighter tolerances = more production time and higher cost. Simply changing the default tolerance values in your CAD program can reduce costs immediately.

- Use standard components instead of custom-drawn parts. Standard off-the-shelf parts cost less. Working with standard fittings, tubing, elbows, and diameters will reduce the amount of custom work required on a chamber.