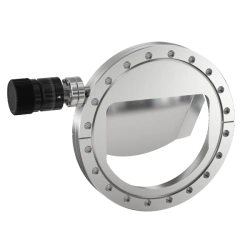

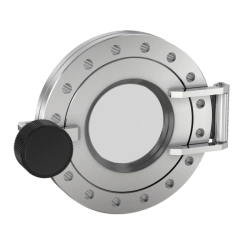

Vacuum Viewports, Shutters, and Doors

- CF flanged viewports are available with fully annealed 7056 glass or fused quartz.

- Unique materials and coatings, such as sapphire and anti-reflective (AR) coating, are available on request.

- Glass provides a significant distortion-free viewing area at a low cost.

- Quartz provides superior ultraviolet radiation transmission and resistance to thermal shock.

- Glass CF flanged viewports can withstand repeated bakeout cycles to 400°C and vacuum pressures to 10-11 Torr.

- Quartz CF flanged viewports should not be baked above 200°C. NW and ISO flanged viewports can withstand 200°C bakeouts and pressures to 10-9 Torr.

Questions About Vacuum Viewports?

Our experts are available to answer any of your questions from design, manufacturing, quality assurance, or anything else you need! If you don't see your question below, contact us.

How do I prevent cracking my viewport?

Viewports can crack from mechanical stress and thermal stress. Thermal stress is caused by uneven heating during the process, leading to uneven stress in the flange. Mechanical stress during installation can be reduced by tightening the flange bolts in small, even steps in a cross-pattern.

What is a differentially-pumped rotary seal?

A differentially pumped rotary seal allows 360 degrees of rotation through the vacuum wall of a UHV system. It can be pumped down independently from the chamber through a dual-port pumping system.

What is an explosion bond?

Explosion bonding is a method to combine dissimilar metals in a vacuum-tight seal. An explosive charge compresses and welds two metals together to become a single piece. Explosion bonds are helpful for transitions between solid chamber walls and malleable sealing surfaces.

What is the difference between Vented and Non-Vented vacuum bolts?

Vented screws have a vent hole drilled through the length of the bolt. In applications where a blind bolt hole is needed (where the bolt hole does not go through the metal), the vented bolt allows trapped gas behind the bolt to be pumped out. In applications where both ends of the threaded hole are exposed to vacuum, a non-vented bolt can be used because there is no trapped gas.